CNC Vacuum tables

Inexpensive vacuum tables for holding sheet materials

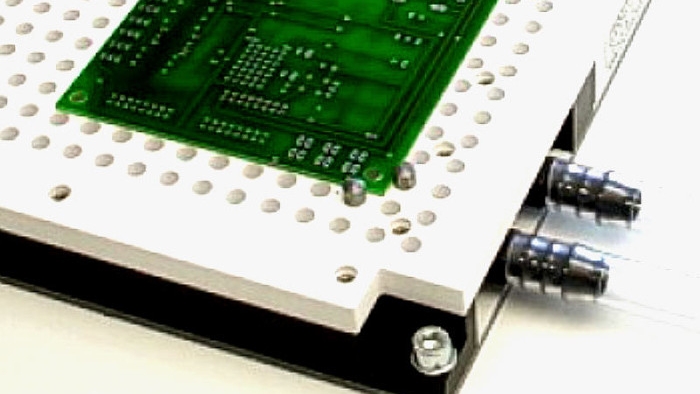

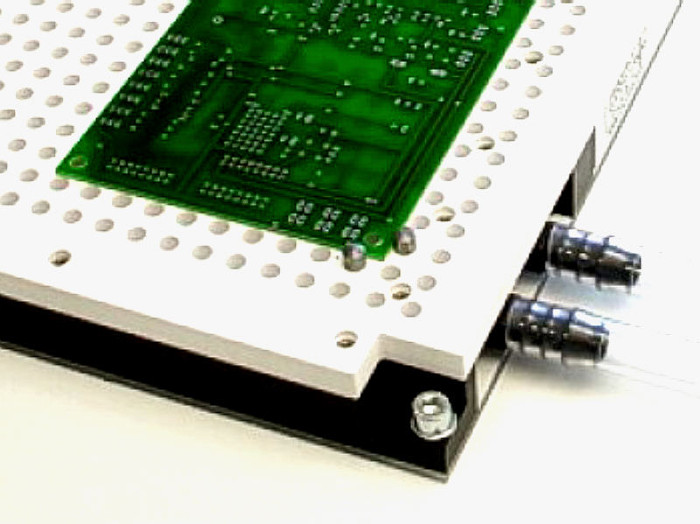

These vacuum tables are ideal for budget conscious users. They can be connected to a regular ShopVac or other dust collection system to hold a variety of parts without further mechanical clamping. They are particularly good for sheet goods of many kinds.

The white plastic top can be surfaced with a fly cutter for ultimate flatness.

A rubber mat that lets air through is provided as a sacrificial layer when cutting through your stock.

Advantages of this vacuum clamping technology

- Reduce the time for clamping sheets by 70%-90%

- Vibration-free clamping of thin and elastic materials - equal holding force across the entire surface

- Easy assembly and handling.

- 6mm bore holes with C-C 10mm across the vacuum table surface.

- Use locating pins for batch/mass production

- High clamping force per square meter through 6mm holes

- vacuum connectors on all sides so you can connect several tables together

What's included

- Sacrificial rubber mat that also provides 30% better adhesion by increasing horizontal friction.

- Shop vac connector

- Connecting hoses

- A4 Special film for covering unused working surface

- 4 x pins 6x14mm and4 x pins 6x18mm

What else do you need?

You need a vacuum source. Many people use a Shop vac, a central vacuum system, a compressor with a venturi adapter, or a vacuum pump.

Learn more about vacuum clamping systems in general from CNCCookbook.

VACUUM TABLES

- Reduce setup time by 70-90%

- Form stable design

- Max flow design

- Connect several tables together

- Easy setup

- Great price

- Quality - Made in Germany

Sizes

- 220 x 320 mm

- 300 x 400 mm

- 300 x 450 mm

- 300 x 600 mm

- 400 x 600 mm

- 400 x 700 mm

- 400 x 1000 mm

- 600 x 1000 mm

- 1000 x 1000 mm

- 1500 x 1000 mm

Need to see some action? go ahead...

Not had enough yet? No problem.

Head on over to the Tube and browse there instead...